We are specialize in repairing the follwoing products:

Chillers

Our service team takes great pride in rapid high quality repairs, which are necessity to high technology industry. We offer services towards all types of chillers be it air cooled, water cooled, screw/scroll/reciprocating or even with open type compressors. Water chillers, oil chillers, glycol chillers, hydraulic oil chillers & many more

What is a Chiller?

Chillers are refrigeration devices. There are different forms of refrigeration, but the most common is the vapor-compression cycle. A typical vapor-compression cycle has four mechanical components that circulate refrigerant in a closed loop: a compressor, condenser, metering device, and evaporator. Main industrial applications: Molding equipment / Induction heating equipment / Welding equipment / Numerically controlled machines / Bakery / Chemical operations / Food processing / Machine tools / Cooling jackets-mixers, ovens / Oil base coolants in drilling / Boiler feed sampling / Cement mixing / Lasers / Packaging machinery / Computers / Plasma cutting / Film processing / Electric generators / Plating tanks / Fish tanks / Blower pressure air/gas cooling / Compressed air/gas cooling / Spot cooling for equipment.

Panel Air Conditioners

Heat inside an electrical enclosure or equipment cabinet can decrease the life expectancy of automation control units such as your PLCs, HMI operator panels, AC drives and other devices. Excessive heat can cause nuisance faults from your electrical and electronic components: like overloads tripping unexpectedly. We offer extensive service support for all types of panel air conditioners, be it designed & manufactured anywhere across the globe

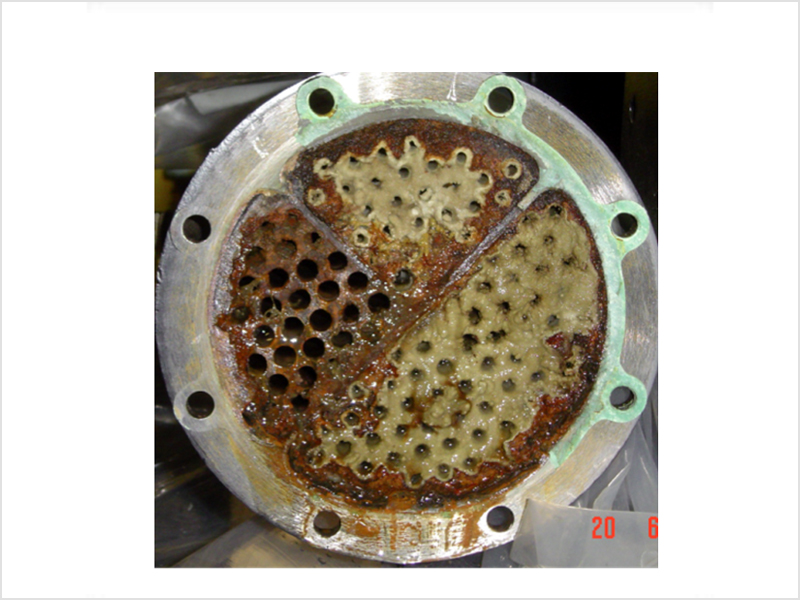

Chemical Descaling Of Heat Exchanger

We undertake chemical cleaning job works of copper coils used in furnace for jacket cooling. The job work includes flushing of copper pipes with special chemical to remove scaling acquired due to water residues. We also chemically clean Chiller Condensers, Heat Exchangers, DG Radiators, and After Coolers.

Air Dryers

Refrigerated air dryers remove moisture and contaminants from compressed air by chilling the air to a temperature that causes the moisture in the air to condense and form droplets. These can be separated from the air stream and discharged from the dryer. This type of dryer uses a refrigeration system, heat exchanger, separator, and drain to perform the drying operation and provide compressed air that is useful for a broad range of applications. This revolutionary technology provides high air drying efficiency, resulting in low operating cost.